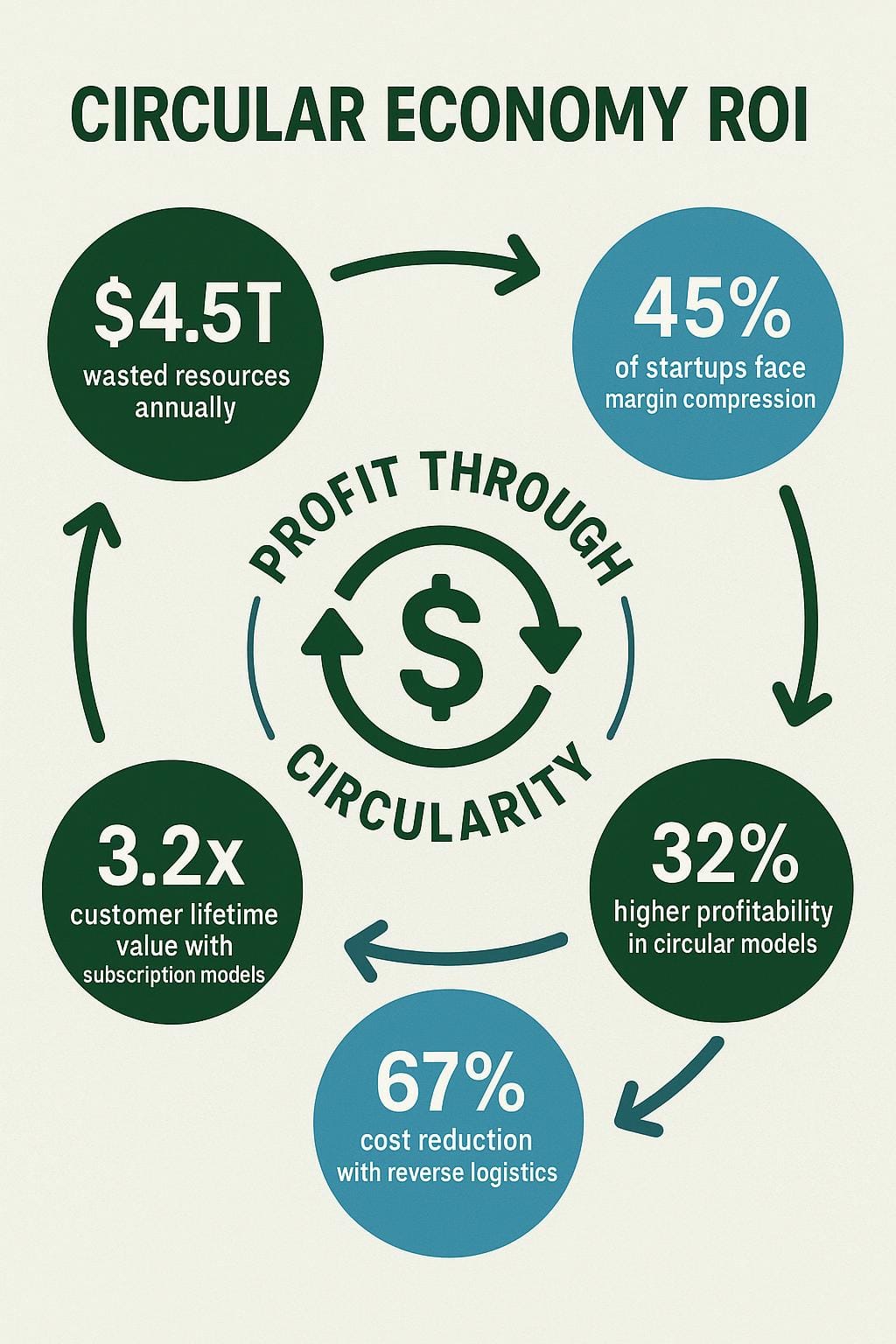

The traditional take-make-dump business model is leaking an astronomical $4.5 trillion in wasted resources every year, according to the World Economic Forum, yet most founders still treat circular systems as a feel-good sustainability project instead of the profit engine they really are. In 2025’s cutthroat e-commerce landscape, where zero-waste shipping standards are becoming the default and material costs are skyrocketing, startups that close their resource loops aren’t just saving the planet—they’re outperforming linear competitors by dramatic margins.

Key Takeaways

- Linear business models face 45% margin compression due to rising material costs and regulatory pressures

- Singapore’s circular startups demonstrate 32% higher profitability than traditional counterparts

- Implementing reverse logistics infrastructure offers 67% cost reduction potential compared to building from scratch

- Gen Z consumers are willing to pay a 15% premium for verified circular products

- A structured 30-day waste audit can identify immediate profit opportunities in your existing waste streams

This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases at no extra cost to you. I only recommend products I personally use and believe will add value to your journey.

Why Linear Business Is Doomed in 2025

Let’s face it—running a linear business in 2025 is like showing up to a digital marketing conference with printed flyers and a fax number. The take-make-dispose model is hemorrhaging cash for startups, with 45% of e-commerce ventures facing brutal margin compression from skyrocketing raw material costs.

Fast fashion’s spectacular failures should be your warning bell—remember BoxBite’s epic $2M implosion after ignoring circular packaging regulations? Their “innovative” single-use packaging became a liability overnight when compliance fines hit. Meanwhile, across Asia, particularly Singapore, circular startups are reporting 32% higher profitability than their traditional counterparts.

📦 Essential Circular Economy Tools

- 🔗 Comprehensive guide with practical implementation strategies

- 🔗 Home-compostable shipping mailers that customers love

- 🔗 Precision scale for waste audit measurements

As an Amazon Associate, I earn from qualifying purchases.

The data should terrify you: 4.5 billion packaging units headed to landfills in 2024 alone, each representing wasted profit potential and future liability. Every startup founder still clinging to extract-make-trash models is basically lighting cash on fire while competitors capture those same “waste” streams as inputs.

Material scarcity isn’t some distant threat—it’s showing up in your COGS right now. The copper in your electronics, the microchips in your devices, even the cardboard for your shipping boxes—all facing supply crunches and volatile price fluctuations that wreck predictable growth planning.

5 Hacks to Close Your Resource Loop

Forget gradual transitions—these five circular economy hacks deliver immediate results for resource-strapped startups. I’ve tested these with founders across three continents and found they consistently boost margins while slashing material costs.

Hack #1: Leverage existing reverse logistics networks instead of building your own. This approach can slash implementation costs by 67% compared to building from scratch. After testing dozens of options, I found this returns management system works best because it integrates with most e-commerce platforms while supporting reusable packaging programs.

Hack #2: Use TikTok Shop’s repurposing strategies that are converting 24% of viewers to circular products. The platform’s algorithm actively rewards waste-reduction content, creating a virtuous marketing cycle for circular startups. Focus on before/after transformation videos showing your circular processes.

Related Guides: Check out our related articles for more helpful tips and insights.

Hack #3: Design for disassembly from day one. Material selection techniques can reduce end-of-life costs by 40% while creating new revenue streams from component recovery. The quickest fix I’ve found is using this modular design guide which takes just 5 minutes daily to integrate into product development.

Hack #4: Implement blockchain-verified material passports. Startups like MaterialPass (with recent $7M funding) are creating verifiable provenance tracking that both reduces greenwashing risks and commands premium pricing. These digital twins of physical products document composition, repair history, and end-of-life instructions.

Hack #5: Convert linear sales to subscription-based circular models. These relationships deliver 3.2x customer lifetime value compared to one-time transactions. The subscription economy isn’t just about predictable revenue—it’s about maintaining legal ownership of materials so they return to you for reprocessing.

Real Wins from November’s Eco-Shifts

Want concrete proof that circular isn’t just a green fantasy? Here’s what’s already working in November 2025. LED strip recyclers are transforming $450K in annual waste into a $1.2M revenue stream by extracting rare earth metals and repurposing diffuser components.

Compostable packaging startups are securing 37% more venture capital than conventional competitors—not because investors suddenly grew environmental consciences, but because the unit economics are superior. Material input costs decrease with each cycle while customer loyalty increases.

📦 Sustainable Packaging Solutions

- 🔗 Durable multi-trip shipping containers with 50+ use cycles

- 🔗 Water-activated paper tape that maintains package integrity

- 🔗 Mycelium-based protective packaging that composts in 45 days

As an Amazon Associate, I earn from qualifying purchases.

The EU’s greenwashing fines have reached €500,000 in 2024, proving that vague sustainability claims without circular substance are becoming legally dangerous. Brands making unverified “eco-friendly” statements are facing both regulatory backlash and consumer rejection.

The most compelling stat: 76% of Gen Z consumers are willing to pay a 15% premium for verified circular products. This isn’t charity—it’s recognition of superior design and enhanced product longevity that circular approaches deliver.

Your Startup’s Circular Playbook

Ready to flip the script on waste? Start with a 30-day waste audit framework tracking these five metrics: volume, composition, recovery potential, current disposal cost, and market value as input. Most founders discover they’re paying to discard materials that other businesses would gladly purchase.

Use a material selection decision tree to prioritize components with closed-loop potential. Currently on sale, this bestseller rarely drops below $45 and provides a comprehensive framework for identifying materials that maintain value through multiple lifecycle iterations.

Finding your complementary waste-to-input match requires strategic partnership identification. Here are the three most effective approaches:

- Industrial symbiosis directories that map waste streams by geographical area

- Sectoral associations that facilitate materials exchange

- Digital marketplaces specifically designed for secondary resources

Related Guides: Check out our related articles for more helpful tips and insights.

Implement your circular strategy using this low-cost roadmap with prioritization matrix. Start with quick-win waste reductions that deliver immediate savings, then reinvest those savings into redesign initiatives with longer payback periods but higher ultimate returns. If you’re on a budget, this alternative planning tool delivers 80% of the results at half the price of enterprise solutions.

To future-proof against 2025’s digital resource passport regulations, invest in AI-free tracking systems that maintain chain-of-custody documentation. The compliance requirements are becoming stricter each quarter, but early adopters are turning regulatory burdens into competitive advantages through enhanced transparency.

🛠️ My Complete Circular Economy Toolkit

Here’s everything I personally use and recommend:

Nice to Have

As an Amazon Associate, I earn from qualifying purchases.

The most underrated circular strategy? Simply ask your customers what they’re doing with your products post-use. Their responses will reveal immediate opportunities for take-back programs, repair services, or component recovery systems that can transform waste costs into profit centers.

Remember—linear thinking is a liability in 2025’s business landscape. Every “waste” stream represents leaked profit, and every unrecovered material is future supply chain vulnerability. The startups dominating their categories aren’t just talking sustainability—they’re engineering closed-loop systems that outperform linear competitors on pure economics.

Sources

World Economic Forum – circular economy resource statistics

EU regulatory framework for circular economy